1. Process Introduction

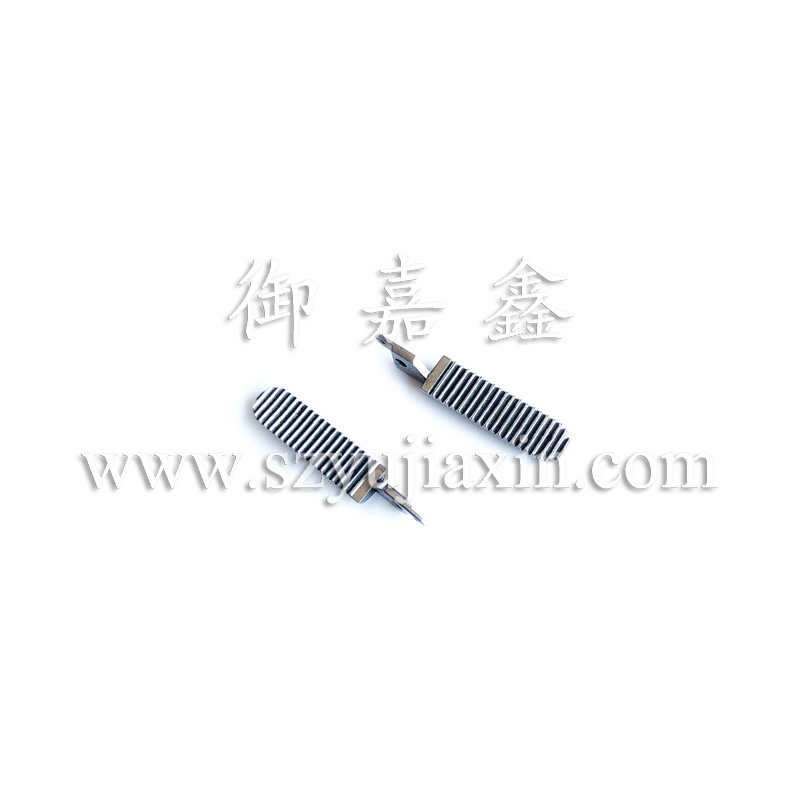

Metal Powder Injection Mold, also known as MIM, is a metal powder injection molding. It is an interdisciplinary advanced technology that uses injection molding to manufacture complex and precise alloy parts. It uses a specially designed metal powder (micrometer level) mixed with high-quality polymer plastic to form MIM feed, which can provide good fluidity during injection and shape the blank through injection molding. After efficient degreasing and sintering, the density of alloy parts can reach 99% of the theoretical density. Metal powder injection molding products have uniform density, good smoothness, and generally do not require subsequent processing. The utilization rate of raw materials is close to 100%, making it the most revolutionary near net molding technology in the 21st century. The product shown in Figure 1 is a nickel plated stainless steel metal part inside the medical equipment orthodontic frame. The product has a large batch size and a complex structure, with a surface roughness value of Ra0.80 μ m and a dimensional accuracy requirement of IT5 (GB/T1800.1-2009). Due to the difficulty, low efficiency, and high material waste of using ordinary mechanical manufacturing methods, metal powder injection molding technology is adopted to save costs.

2. Structural Analysis of Metal Injection Molding Products

The weight of metal powder injection molded products generally does not exceed 250g, but the size of the product is relatively large, with a weight of about 350g. The maximum external dimension is 171.00 × 67 × 34.50mm, and the average wall thickness is 2.2mm. The weight of the product is one of the difficulties that MIM injection mold structure design needs to face. In addition, the structure of the product is complex, and there are four places that require lateral core pulling, all of which are on the fixed mold side. Lateral core pulling from the fixed mold is the second difficulty that mold design needs to face.

3. Determination of resin and feed ratio and shrinkage rate

The particle size of nickel added stainless steel metal powder is 0.2 μ m, and the organic adhesive uses nylon PA12. It is the carrier of the metal powder, which is used to bond the metal powder particles, making the feeding material have rheological and lubricating properties after heating in the injection machine barrel. The advantage of nylon is that it requires less amount and does not react chemically with metals, making it easy to remove during degreasing. Referring to foreign experience and previous experimental results of our institute, the volume ratio of nickel stainless steel and PA adhesive mixture is 8:2. During the degreasing process, the volume of the components will not change, but during sintering, the components will experience 13% to 18% shrinkage. Therefore, the shrinkage rate is much larger than that of a simple PA injection mold. According to the feeding ratio, the mold size adopts a 15% shrinkage rate.

4. Mold structure design

In order to solve the problem of large weight of formed blanks, the mold adopts a pouring system with four point gates to evenly feed from the mold cavity. The specification of the mold frame is Longji simplified fine nozzle mold blank, using an internal fixed distance parting mechanism. To prevent safety accidents caused by opening the mold during transportation, the locking buckle should be removed during production.

4.1 Design of formed parts

The feeding of nickel stainless steel+nylon PA12 is sensitive to gaps and can easily produce burrs. Plastic parts with burrs are easy to remove, but metal parts with burrs can cause safety issues like a blade. So the design and manufacturing requirements for MIM injection molded parts are particularly high, and the dimensional accuracy and fitting accuracy must reach IT5 or above. The molded parts adopt a splicing structure to improve the rigidity and strength of the mold and ensure the dimensional accuracy of the formed products. Compared with a single PA plastic melt, the feeding material of "nickel stainless steel+PA" has another characteristic: it has a higher friction force on the mold cavity, and high requirements for the steel and surface roughness of the formed parts. The mold formed parts must use steel with better wear resistance. This mold uses mold steel S136H, with a heat treatment hardness of 30-35HRC, and the surface of the cavity is polished to Ra0.4 μ m to improve the fluidity of the feeding material and prolong the life of the mold. High dimensional accuracy, no burrs, and ultra-high surface quality are all requirements that MIM injection molds must meet.

4.2 Design of lateral core pulling mechanism

The formed blank has two outer side buckles and two inner side buckles, both of which require the design of a lateral core pulling mechanism. The distance between the two inner core pulling mechanisms is 1.7mm. Due to the short distance and small inner space, the mold can only use a slanted top lateral core pulling mechanism. Also, because the inner reverse buckle position is formed by a fixed mold, only a fixed mold inclined top can be used, which is the difficulty and focus of mold design. Because there is no thrust from the injection molding machine's top rod on the fixed mold side, the fixed plate of the fixed mold's inclined top can only be pushed out by a spring and reset by a reset rod. Diagonal top lateral core pulling mechanism. The pushing distance of the inclined roof fixing plate should be strictly controlled within 25mm to prevent interference between the two inclined push rods when pushed out. The inclination angle of the two inclined roofs should not be too large, and this mold takes 7 °.

The injection mold structure includes: fixed mold seat plate, stripper plate, 12. T-shaped buckle pressure block, inclined top, pin, inclined top base, support column, inclined top base, pin, sprue sleeve, fixed template, spring, wear-resistant block, fixed mold slider, moving mold insert, moving mold core, moving template, guide column, push rod fixing plate, guide sleeve, push rod bottom plate, moving mold seat plate, reset rod, side core pulling, fixed mold insert, fixed template insert, inclined top bottom plate, inclined top fixing plate, nylon plug, push pipe, positioning block lower, positioning block upper, limit nail, lock mold buckle, and small pull rod. The two outer inverted buckles are also formed by fixed molds, and to ensure appearance quality, both use fixed molds for lateral core pulling. During the core pulling process, the locking block is always in the T-shaped groove of the slider, so there is no need to design positioning parts for the slider.

4.3 Design of fixed distance parting mechanism

The mold adopts a point gate pouring system, and the mold must use a three plate mold frame. When opening the mold, there are a total of three parting surfaces, including two on the fixed mold side. In order to ensure the automatic demolding of the runner aggregate and the completion of core pulling by the fixed mold lateral core pulling mechanism before the opening of the moving and fixed molds, the opening sequence and distance of the three parting surfaces of the mold should be strictly controlled. Therefore, the mold must be designed with a fixed distance parting mechanism. The mold adopts a built-in fixed distance parting mechanism, which enables the flow channel condensate to fall off smoothly, and at the same time, enables the inclined top and fixed mold slider to smoothly complete lateral core pulling, ensuring that the pulling pin separates from the flow channel condensate.

4.4 Temperature control system design

Due to the high specific heat of metal powder, the mold absorbs more heat during the molding process than ordinary nylon injection molds, making the design of temperature control systems more difficult. According to the shape of the product, the fixed mold adopts one straight through cooling water channel, and the moving mold adopts three cooling water channels.

4.5 Design of demolding mechanism

In metal powder injection molds, demolding and cooling are key issues. After completing the lateral core pulling, the formed billet is finally pushed away from the moving mold by the push rod and push tube. This combined demolding mechanism is sufficient and effective, ensuring the safety, stability, and non deformation of the billet during demolding.

4.6 Exhaust system design

MIM injection molds have significant differences in exhaust groove depth compared to ordinary injection molds. The depth of the exhaust groove in a regular injection mold is generally 0.02-0.06mm depending on the type of plastic it forms, while the depth of the exhaust groove in a MIM injection mold is generally between 0.0025-0.005mm. If it exceeds this depth, it will produce burrs. Good feeding results in extremely low shrinkage during the subsequent solidification process. In order to strengthen the shape retention of formed products as much as possible, a large amount of metal powder filling agent can be used, and its dosage is often close to 70% of the volume. In order to achieve good flowability of high filling feed, low molecular weight plastic PA was used to make MIM feed have high flash sensitivity, similar to the characteristics shown by many filling nylon materials.

5 Mold working process

(1) Mixing materials. Mix nickel stainless steel metal powder and nylon PA12 evenly in a volume of 8:2 to obtain the feed.

(2) Injection molding. Put the feed into the injection molding machine barrel and heat it to 150 ℃, turning it into a viscous paddle like substance. Inject it into the mold cavity through the point gate pouring system under high pressure. Controlling molding parameters such as injection temperature, mold temperature, injection pressure, and holding time is crucial for achieving stable green billet quality.

(3) Cool and solidify. After filling the cavity with feed, it is pressurized and cooled, solidified into a blank, and the mold is opened under the pull of an injection molding machine.

(4) Mold opening. Under the action of the fixed distance parting mechanism, the mold opens sequentially from parting surface I, parting surface II, and parting surface III. The mold opening distance of parting surface I is 145mm, controlled by a small pull rod. When the parting surface II is opened, the mold completes the outer core extraction, and at the same time, the discharge plate pushes the flow channel condensate away from the mold, achieving automatic demolding of the mold. The mold opening distance of parting surface II is 12mm, controlled by limit screws. When the parting surface III is opened, the moving template and the fixed template separate, and the formed blank separates from the fixed model cavity. After completing the mold opening process, the push rod will push the formed blank out of the mold, completing one injection molding.

6 Summary

(1) Compared to other metal forming methods, metal powder injection molding can manufacture products with more complex shapes, with high efficiency and no material waste. It is a typical precision manufacturing and green manufacturing technology. But the size of the product is subject to certain limitations, generally not exceeding 250g. The product formed this time weighs 350g, which is a breakthrough and successful attempt for metal powder injection molding.

(2) Compared with pure nylon PA, the nickel based stainless steel+PA feed has poor plasticity, and the risk of using fixed mold inner and outer core extraction is high. This success is also a major breakthrough in the bold innovation of mold structure.

(3) The mold structure is advanced and reasonable, with a successful trial run. After the mold is put into production, it runs safely and smoothly, with a molding cycle of 28 seconds and a daily output of up to 2300 pieces. After degreasing sintering, the dimensional accuracy of the formed blank reached IT5 (GB/T1800.1-2009), and the surface roughness value reached Ra0.8 μ m, both of which met the design requirements.

---Reprinted from the monthly magazine "Mold Manufacturing" by Zhang Weihe, Cheng Yongtao, and Xu Yonglin (Guangdong University of Science and Technology)